After investing money in new technology, we expect it to work as intended, no matter the task. Many industries rely on tools and applications that require accurate testing and measuring, but these can lose their accuracy over time. If left unnoticed, this situation can lead to measurement errors that adversely affect performance and precision. Depending on the tool, a lack of accuracy can cause you to waste your valuable time recalculating the measurements or lead to dangerous mistakes.

Read on to learn how to calibrate PXI cards in our guide to PXI card electronic calibration.

You don’t always need to throw away old tools and purchase new ones. Often, recalibrating machines is all it takes to get them working correctly again. That’s why routine calibrations are essential to keep your tools in working order.

Calibration allows you to maintain accuracy, standardization and repeatability in your tools. Adequately calibrated equipment will provide reliable results. When tools go a long time without proper calibration, they will give inaccurate measurements or improper performance, impacting quality and safety. Regular calibration ensures high-quality tools that perform as expected.

If you have the time, equipment and knowledge, you can calibrate your tools yourself, or you can rely on the professionals to do the job for you. When choosing the latter, you can rest assured your technology will always come back fully calibrated and functioning accordingly.

PXI — short for PCI eXtensions for Instrumentation — is a testing system that offers a solution for measurement and automation. Engineers use PXI to build mixed-measurement systems for applications like production tests and validation procedures.

PXI provides users with cost-efficient, high-performance flexibility that pairs with the latest PC technology, incorporating integrated timing and triggering to create a durable solution. With PXI, you’ll notice a remarkable performance improvement when compared to other testing and measurement methods.

PXI cards are the primary component that provides your PXI system with high-performance capabilities. These cards make up the internal components of the chassis, which houses and reads the cards. The chassis allows your PXI test system to read and use the PXI cards while also providing the necessary components for them to operate. The chassis contains numerous mechanical cardholders, a power supply to activate the cards and a cooling system to ensure the PXI cards do not overheat.

PXI cards work as the primary source for your test system’s interface. These cards provide individual instrumentation functions while mounted to the chassis. They are flexible, meaning they can add and reconfigure the hardware to the base architecture. Simultaneously, PXI cards integrate various software that optimizes the PXI test system performance.

PXI cards come in a broad range of sizes, variations, purposes and specifications, giving them the versatility to conform to an array of applications. Because of the wide selection of PXI cards and their different functions and specifications, many people turn to an industry expert who knows the ins and outs of this technology. They provide these experts with the necessary information on how the PXI system should operate, and the experts can quickly and easily find the right PXI cards the first time.

However, if you’d prefer to do the research, time and experimentation to find the best PXI cards yourself, you should consider these four specifications to ensure you get the most out of your PXI card.

Bandwidth

Bandwidth is the measure of how quickly data transmits between two points. The higher the bandwidth, the faster you’ll be able to transfer data from one source to another. Manufacturers measure bandwidth in megabytes per second or gigabytes per second.

BIOS

When you use your PXI cards, they have an initial startup time that delays how quickly they come into effect. Basic input/output system (BIOS) is a firmware that initializes the system during startup and aims to reduce the time it takes your PXI card to boot up.

CPU Performance

To maximize the software you can run off one PXI card, you will need one with a high CPU performance. CPU relies heavily on the PXI card type, and with the right card, you can run multiple applications simultaneously without the system overloading or straining. You will need to appropriately balance the CPU performance, the number of applications running and the cost of computational speed.

Motherboard Space/Connections

Each PXI card has a designated number of motherboard connections. You will want to get ones with enough to allow you to use the system as desired. The available slots and surface area help dictate the system architecture. Once you’ve made your connections, you will have to check, test and verify their compatibility with the motherboard and the test system.

PXI test systems are a complicated series of connections, cards and interfaces all working together to perform their functions. If any of these pieces stop working as intended or the calibrations vary slightly, this deviation can cause system failure or inaccurate readings, leading to unusable data. You will need to keep your system calibrated, especially your PXI cards.

Over time, your PXI cards’ inputs/outputs will gradually drift, skewing results and leading to unexpected performance. Because of this drift’s effects on your PXI test system, you will need to have them calibrated regularly to keep their readings accurate.

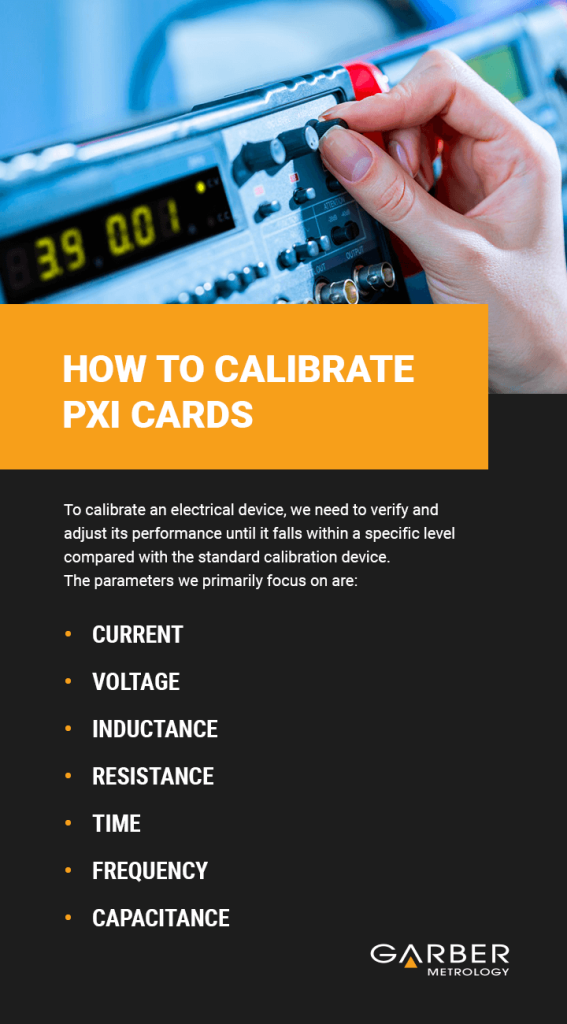

To calibrate A PXI card, you need to take readings compared to a standard calibration device. The parameters primarily in focus are:

Those who calibrate PXI cards compare measurements in each of these categories with those found in the standard of reference. From there, they gauge whether the unit is within the manufacturer’s specifications and will adjust the unit back within these specifications when it is not, if possible.

There are three primary resources necessary to achieve maximum accuracy when calibrating. Each resource allows for a series of intricate and meticulous tasks to ensure proper calibration.

First, calibration experts use specialized equipment to adjust your equipment with extreme precision. Many electronic devices have tiny moving parts and connections, especially on a PXI card. Individuals calibrating these devices need tools that allow for completing the job without fear of over-adjusting or damaging the parts.

Second, the calibration procedure must follow the various industry regulations and regulatory institution standards. All the tools used for calibration must conform to applicable standards. The processes followed must also abide by specifications, depending on the instrument used. These rules and regulations ensure the calibration does not deviate too drastically, and it requires documentation to show when and what a company did to calibrate.

Finally, calibration experts need the training and practice to perform these precise calibrations without risking internal or external damage. Calibration is an intricate and complicated process that can easily ruin your device’s output. Relying on untrained or inexperienced partners can risk breaking your equipment. That’s why those who perform calibration must have the necessary training to keep them abreast of the latest calibration tools, procedures and processes.

Remember that calibration is never a permanent fix. It merely allows your device to continue performing at the desired output for an average of six months to a year. For continued, optimal usage, regular calibration should be part of your preventive maintenance strategy. The calibration frequency ultimately depends on the usage of the instrument, the environment in which it operates and other factors.

Before you send in your device for calibration, you should always have a backup tool or adjust your processes. Calibration takes time, depending on the instrument, age, how often and how you use it, environmental conditions and how you store it. All these factors can affect project efficiency. You should contact a calibration professional, receive a recommended estimate on how long the process will take and then plan accordingly.

When you send your equipment to most calibration companies, they tend to take a long time to get your equipment back to you. . The problem with this is pretty apparent as you’ll be without your equipment for a long time.

At Garber Metrology, we take time to calibrate your equipment to the best of our ability every time, as quickly and accurately as possible. Here at Garber Metrology we operate on a 5 business day turnaround so we can get your crucial equipment back to you within the week. We run extensive tests and compare the unit against a much more precise calibration standard. For the best possible calibration, we use a standard with at least 4 times your equipment’s accuracy. This precision helps us ensure your tool measures as correctly as possible.

Contact us online to learn more about our PXI card calibration services.